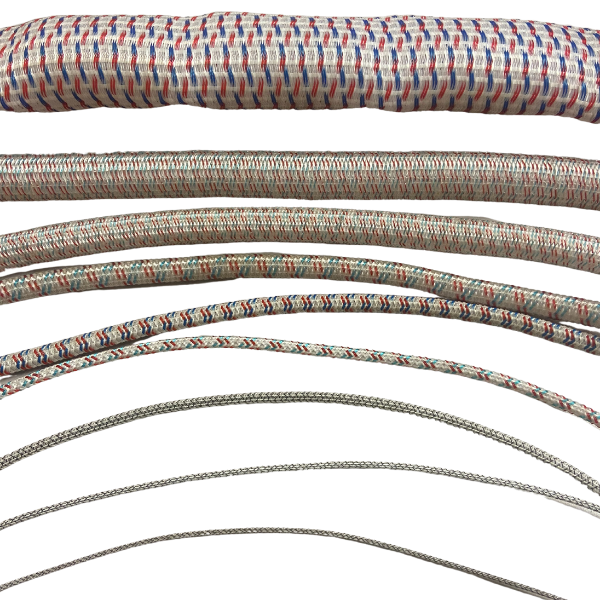

Core Vent

Core vent or core tubing is used inside molds to allow gasses to escape preventing unwanted gas defects. Core vents are a unique venting solution that maintains the integrity of the vent space throughout the compaction process. Core vent improves casting quality by allowing gases and air to escape more readily during the casting process. Core vents can be placed in either the mold or core. The core vent is made with fibrous materials that break down during pouring, making the sand reclamation process more efficient. The core vent is offered in various sizes, from 2″ to 1/16″ of an inch. Our core vent is made here in the USA and provides greater permeability than vent tubing imported from China.