Mulling Mixer: Innovative Solution for Sand Mixing

When it comes to industrial mixing, performance, reliability, and efficiency aren’t just nice to have — they’re essential. Whether you’re running a green sand foundry or producing high-performance precast materials, the equipment you choose sets the tone for everything that follows.

At Mixer Systems, they engineer standout solutions that are changing how companies approach mixing with the SandMASTER™ Mulling Mixer. American-made, precision-built, and designed with your bottom line in mind.

What Is a Mulling Mixer?

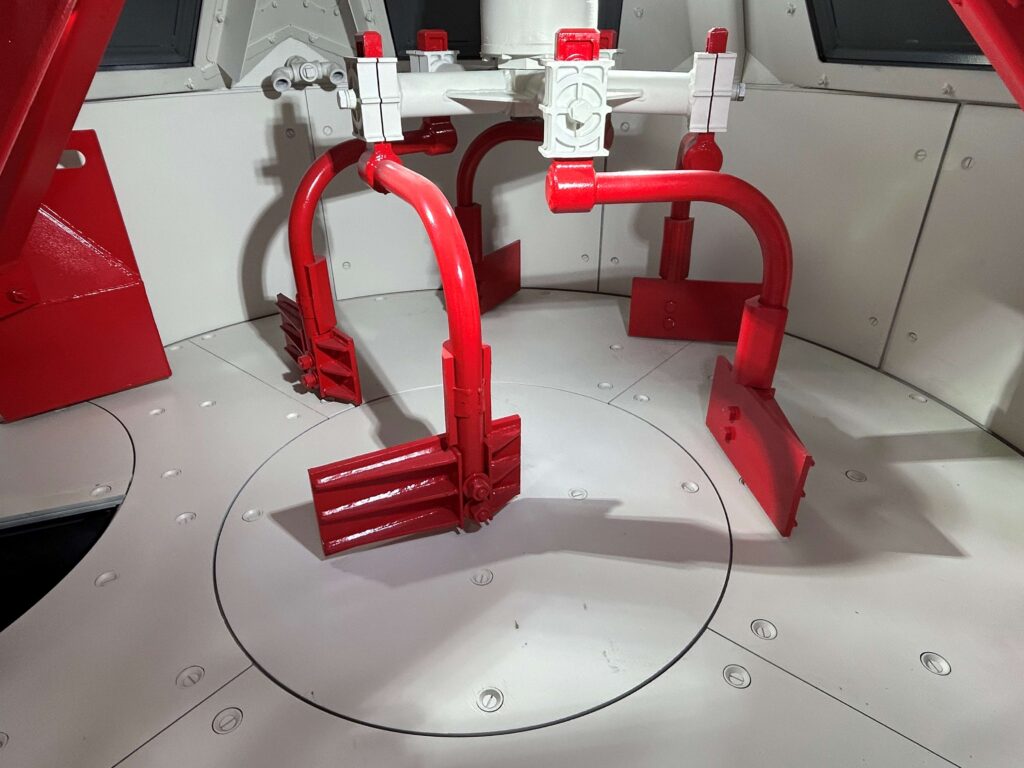

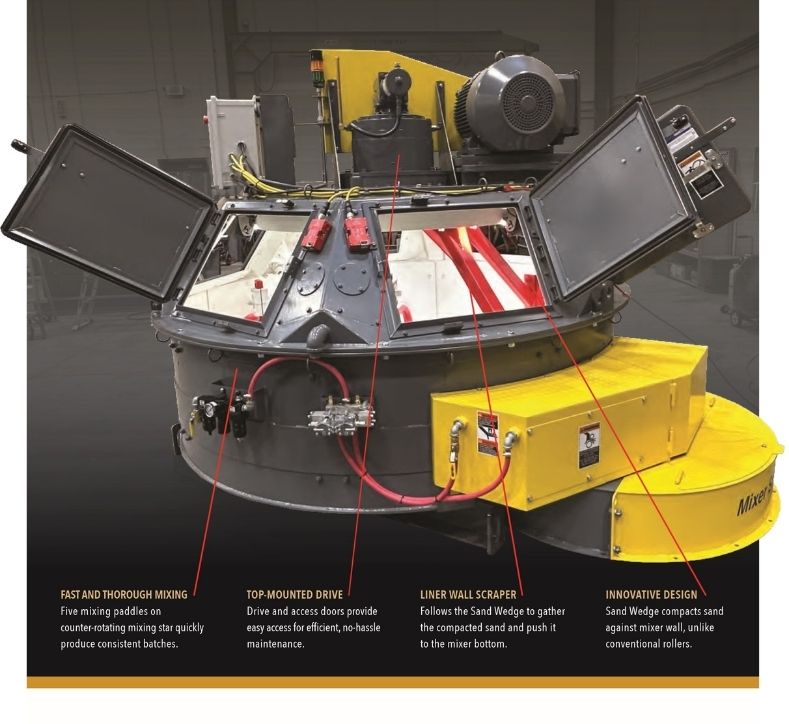

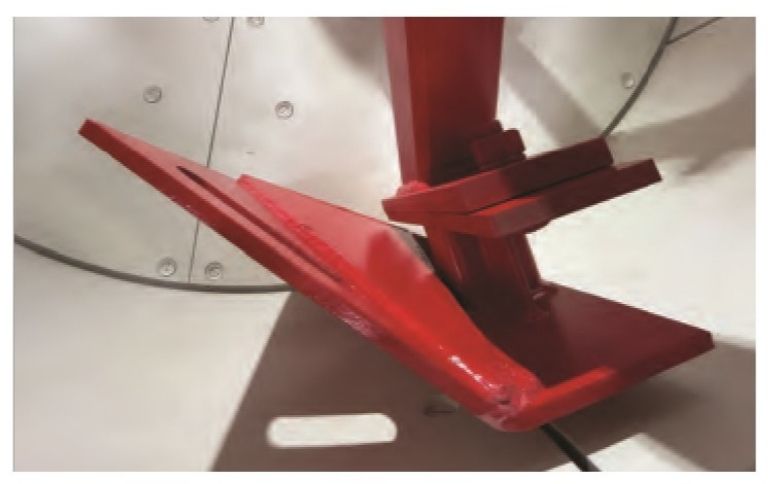

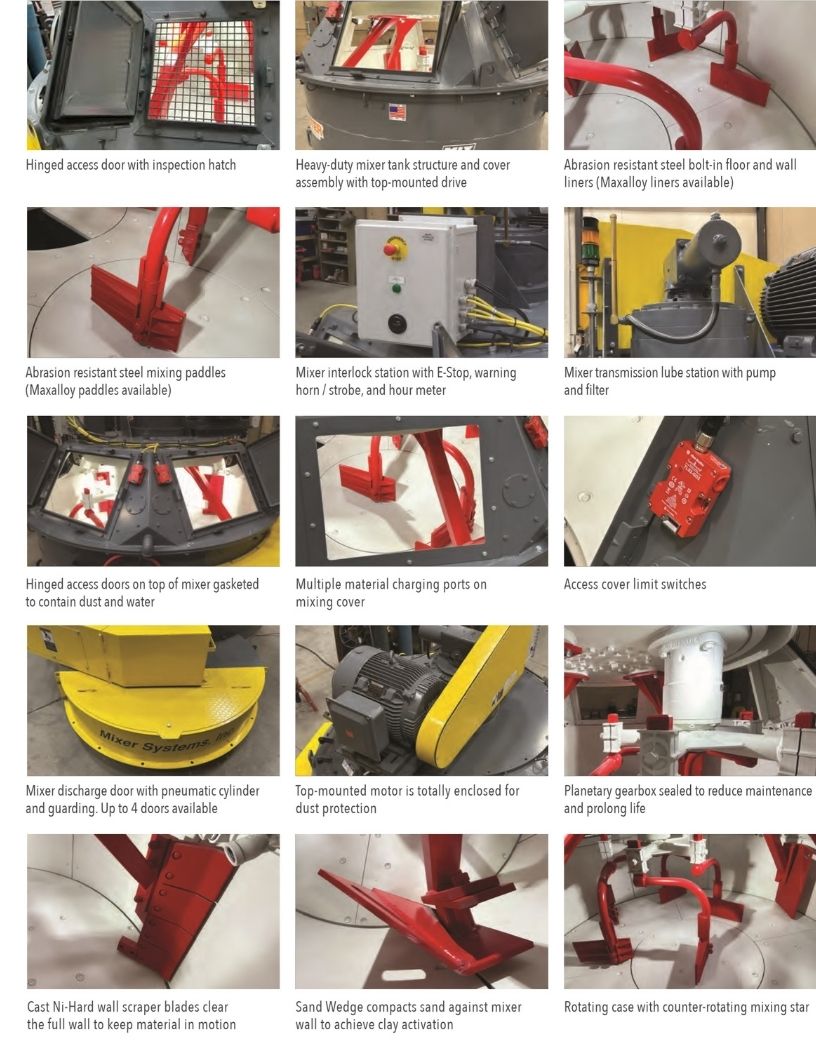

A mulling mixer is a specialized piece of equipment used in foundries to prepare sand for molding processes. Green sand is a mixture of silica sand, clay, water, and sometimes additives, and it must be thoroughly mixed and conditioned to ensure it has the right consistency and bonding properties. The mulling mixer combines these ingredients by thoroughly agitating the sand with clay, activating the clay particles, and ensuring an even distribution of moisture and additives. This process helps to improve the strength, cohesion, and durability of the green sand, which is essential for creating high-quality molds in metal casting. The mulling mixer uses the Sand Wedge™ blades to activate clay, break up lumps and ensure that the sand grains are uniformly coated with clay, optimizing the compatibility of the sand.

Why It Matters:

- Consistent Quality: The counter-current action ensures all materials are fully blended, delivering a homogeneous mix in as little as 30 seconds.

- Time-Saving: Faster mixing means higher throughput and less idle time.

- Designed and Manufactured in the USA: Mixer Systems, Inc. is proud to be the only manufacturer producing this type of mixer domestically, giving you the benefits of U.S. quality and support.

Meet the The SandMASTER™ Mulling Mixer

If you’re in a green sand foundry, your success depends on the quality and consistency of your sand mix. That’s where the The SandMASTER™ Mulling Mixer comes in — a lab-tested, field-proven mulling mixer that uses revolutionary rollerless technology.

Sand Wedge Feature

At the heart of the SandMASTER™ Mulling Mixer lies the innovative Sand Wedge™ design, a key feature that sets it apart from traditional mulling systems. Unlike conventional mixers with rollers, the Sand Wedge™ design compacts the sand tightly against the mixer wall. This action activates the clay and ensures a uniform coating of the sand grains. By tightly compacting the sand, the system effectively smears and coats each grain with clay, which is crucial for achieving a high-quality green sand mixture. This precise and efficient process is essential for producing consistently excellent results in foundry operations, making the SandMASTER™ Mulling Mixer a standout choice for ensuring optimal sand preparation.

Key Highlights:

- No Rollers: Less wear, less maintenance, and simplified operation.

- Lower Total Cost of Ownership: With fewer moving parts, you’ll spend less on repairs and downtime.

- Engineered for Foundries: Abrasion-resistant components, easy-access doors, and intuitive design make this mixer ready for real-world demands.

Why Choose Carpenter Brothers, Inc. and Mixer Systems, Inc.?

Choosing the right mixer isn’t just about specs — it’s about finding long-term value and a partner that stands behind their equipment.

- American-Made Excellence: The SandMASTER™ Mulling Mixer is designed and built in the USA.

- Engineered for Performance: Each machine is optimized to reduce waste, improve consistency, and cut operational costs.

- Tested and Trusted: Backed by lab results and real-world use in some of the toughest environments.

With over 45 years of experience building industrial mixers, Mixer Systems understands exactly what it takes to succeed in demanding environments — especially in foundries. They don’t just build mixers; they build robust, heavy-duty equipment that’s engineered to withstand the extreme wear and tear that foundry operations dish out every day. Because they already work closely with foundries across the country, they know what’s needed: durability, reliability, and consistent performance. That’s why every Mixer Systems product is built not just to run — but to last.

Final Thoughts

If you’re looking to increase casting quality, reduce downtime, or streamline your mixing process, now’s the time to take a closer look at The SandMASTER™ Mulling Mixer. Working with precision materials or foundry sand, these machines represent a smarter, more efficient way forward.

Questions? Want to see them in action? We’re here to help — contact Carpenter Brothers, Inc. for more information.