Grinding Wheels

Grinding wheels are used to remove excess metal and prepare casting finish.

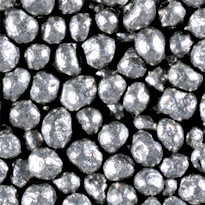

Grinding wheels are produced in varied sizes, grits, and shapes to customer needs. Since castings are of all different shapes and sizes, wheels need to be made to be able to clean and/or remove metal from any area of the casting. Wheels are also produced in different compositions to achieve different goals. Speed, wheel life, size, and cost are all factors to consider. Most wheels are made of silicon carbide and binder. However, any needed abrasive media can be formulated to need. Recent years has seen an uptick in diamond glazed wheels. These wheels are predominately used in auto/robotic grinders, but some are used in hand grinders.