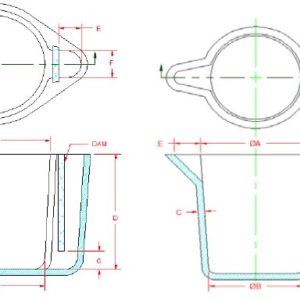

Hot Pour Ladles

Hot pour ladles are vacuum-formed with a wire basket inside for added strength and improved life. Hot pour ladles were designed to pour aluminum or zinc as a ladle liner or in a pouring shank. Vacuum-formed products are both compressed and bonded have significantly greater density than non-bonded ceramic fiber. As a result, they are 33% more efficient than non-bonded fiber. In addition, heat flow through the vacuum-formed fiber is significantly reduced, leading to more consistent metal contact. When these characteristics are considered in terms of ladles and ladle liners, these products offer definite advantages over typical ladles and ladle liners on the market.

For hot pour ladles used exclusively in the aluminum market, where maximum protection against contamination of critical alloys is required, the Alfibond® formulation is strongly recommended. Alfibond is an alumiphobic material with exceptional resistance to chemical deterioration by molten aluminum. Alumiphobic describes Alfibond’s lack of affinity or aversion to molten aluminum.

We offer three sizes of the hot pour ladles; L-135 (61lb Al capacity), L-85 (41 lb Al capacity), L-60 (30 lb Al capacity).

- Features:

- Lightweight – weight for capacity is negligible compared to cast iron or dense refractory ladles

- No pre-heating required – highly insulated hot pour ladles reduce heat loss while transporting

- No superheating metal – reduces energy loss and hydrogen absorption in aluminum

- No iron contamination – critical alloys remain pure, gas-free, and at the correct temperature throughout the pour

- Retain structural integrity – hot pour ladles are steel reinforced for safety and durability

- Longer life – hot pour ladles withstand the deteriorating effects of molten aluminum or most non-ferrous or ferrous metals

- Versatile – hot pour ladles can be easily substituted for iron ladles and they mount in existing handles