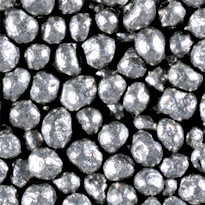

Steel Shot & Grit

Steel shot is a product produced by melting steel to specification, pouring the liquid metal into a high-pressure stream of water, and letting it fall into a pool of water. The resulting violent reaction causes the steel to form small balls. The extremely violent reaction forms small balls of steel. The balls are removed from the water via a screw conveyor or magnet crane. They are then allowed to run down a spiral conveyor. The centrifugal force forces the round balls to spin-off and the non-rounds to stay on the conveyor. The round shot is collected and sized to SAE specification. They are then tempered in a furnace to yield the required hardness. The non-round shot is crushed to make grit. Most steel shot and grit are used in wheel blast machines. Some steel shot is used in ballast for counterweights.

Round Steel Shot

Quenched and tempered, it is a spherical product of hypereutectoid steel (C ≥ 0,85%). Perfectly controlled heat treatments provide it with optimum resilience and resistance to fatigue. This type of shot is used in all applications where the desired effect is for mass and maximum bounce and shot peening.

Angular Steel Grit

A cast steel angular grit is produced by crushing specially heat treated oversize shot pellets. It is utilized for blast cleaning or surface preparation.

GP Steel Grit

Quenched and tempered, angular when new, this grit rapidly rounds off in use and is particularly suited to descaling applications.

GL Steel Grit

Quenched and tempered, although harder than GP steel grit, GL also loses its sharp edges during shot blasting and is particularly suited to descaling and surface preparation applications.

GH Steel Grit

Quenched with a maximum hardness, GH always remains angular in its operating mix. These abrasives are particularly effective in surface treatment processes and produce a uniform, etched finish.

For use mainly with compressed air equipment.